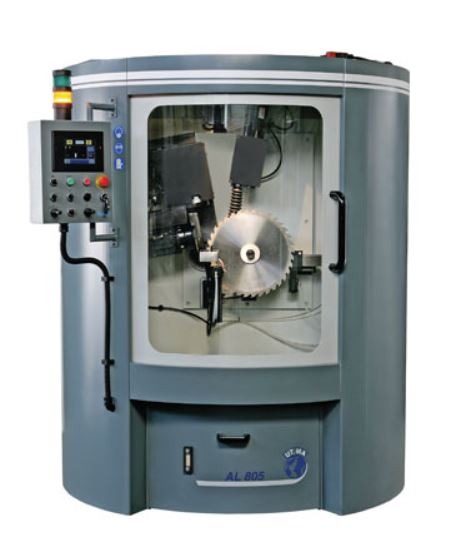

Models: AL805 AL1200 AF801 AF1201 AC400 & AC520

Automatic sharpening machine for circular blades with HM teeth up to a diameter of 800 mm, used for cutting wood in sawmills and carpentry shops.

The AL805 sharpens the internal side of the tooth and the external geometry (trapezoidal, alternate or special) in a single automatic cycle, allowing the operator to save lots of time when carrying out adjustments on the machine.

The AL805 model can be equipped with the following accessories:

– Extraction system (centrifugal or electrostatic)

– Oil filtration system

– Hollow face grinding assembly

– Probe system used to position the grinding wheel on the tooth.

The automatic sharpening machine Model AL1200 can be used to sharpen circular blades with HM teeth up to a diameter of 1200 mm.

Automatic CNC grinder for the sides of the blades, with HM teeth, Model AF801 and AF1201, for grinding sides during the construction or repair phase of the blade, with re-plating of all teeth.

The interpolated movement of the three axes allows grinding of teeth with tapered or radius shape. Blades with diameter of up to 800 mm can be sharpened using the model AF801, whilst the Model AF1201 can be used to sharpen blades with diameter of up to 1200 mm.

AC400 AC520 & AC800

Circular knives are used in many different industrial sectors: paper industry, textile industry, rubber industry, agro-foodstuff sector and many other applications.

By using the UT.MA AC400/AC5200, the grinding operator exits the traditional sharpening circuit of wood and metal cutting tools and has the possibility to increase its customer base by offering them excellent grinding quality. Our grinder models for circular chamfered blades can be used to sharpen HM or HSS circular blades.

They are different from one another due to the maximum diameter that can be sharpened. The main characteristic of our product is given by the 2 types of grinding offered by the machine:

1) sharpening with cup grinding wheel that is constantly in contact with the rotating knife

2) Sharpening with tangential grinding wheel, moving back and forth on the bevel of the rotating knife.

This technology is especially appreciated in some sectors that require the knife to have a lapped surface. The AC400, AC520 and AC800 can be equipped with the following accessories:

– Extraction system (centrifugal or electrostatic)

– Oil filtration system